|

|

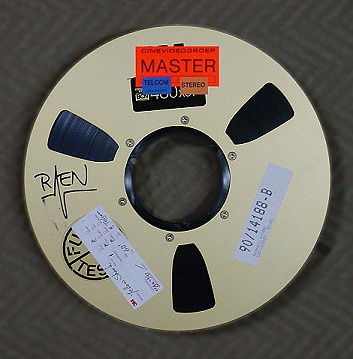

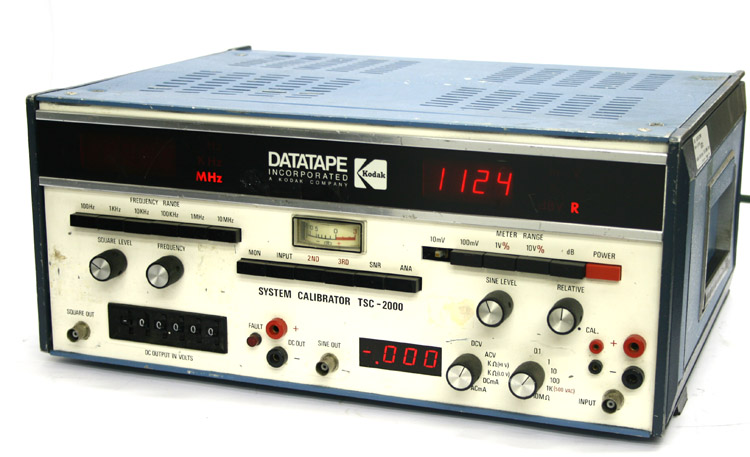

| The Data Evaluation Lab (DEL) at the Goddard

Space Flight Center is the only known place that has the equipment

and expertise to playback the 1" wide magnetic tapes and to recover

data. |

|

|

| |

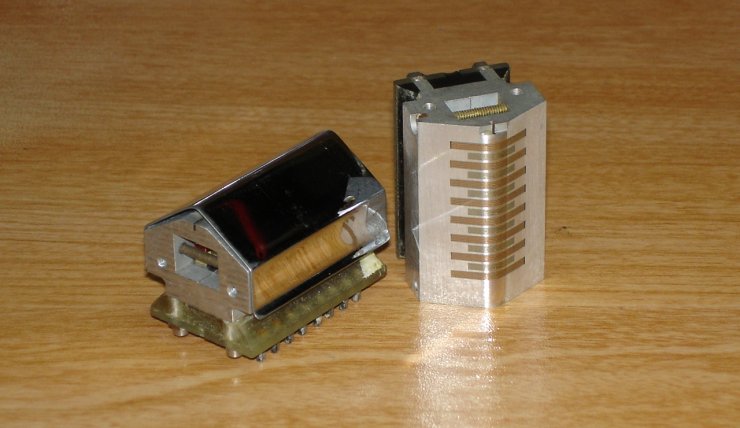

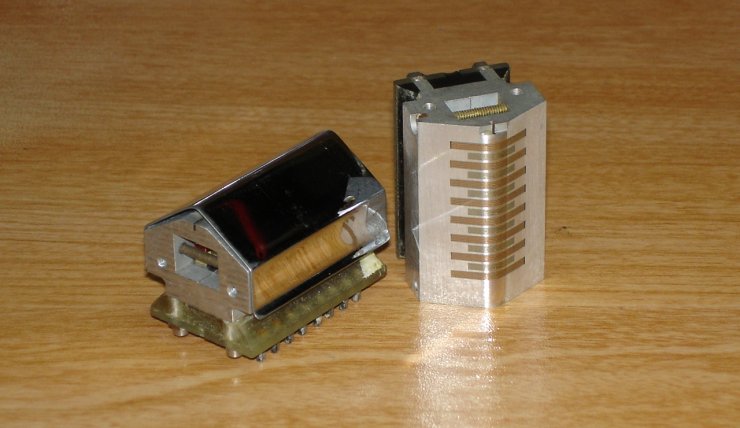

Jackson Research has the original

blue prints (literally) for these capstan motors for the MARS tape

recorder (M-22). The MARS recorder was much smaller than the 3700B,

but used the same magnetic technologies. The motor in the photo

is from a limited production facility in the basement operated

by John Jackson and two others. The shaft is ground from sintered

Tungsten. The optical recorder used a light image pipe to double

the line count for a 10k lines per revolution tachometer built

into the rear of the assembly.

Silver was sputtered onto precision cut optical grade glass

disks. The high line counts were photo etched from very large

photo masks which were optically reduced to minimize mask errors. |

|

|

| |

| The tape recorder capstan motors were

high performance Alnico magnet torque motors in precision machined

housings with integrated optical encoders. The bearings were typically

grade 9. These motors were controlled in closed PLL loops

designed by Eugene Cooper and Henry Martiya. |

|

|

| |

IRIG 28 track assemblies had seperate

record and read interlaced head assemblies resulting in four

heads per assembly. The cores were hot pressed ferrite with sendust

tips. The highest record frequency was around 1.5 MHz with

20dB S/N ratio. These high definition 28 track one inch head

assemblies were used in airports to rrecord all flight date in

the control towers. Also, the marines were using it in intelligence

gathering. Several of the manufacturing phases had been improved

with the last one fine grinding after alignment of the gap depth

in a specially built tool fixture using 15 microinch glass gap

head assemblies in a linear - as opposed to the Ampex quad heads

- video recorder. Also, initial layout of solid state head assemblies

and sputtering of sendust on quartz substrates were made. No

problem with alignment here and 100 channels per inch were easily

achievable. The economy got into a slow down and B&H closed

the lab.

|

|

|

| |

|

| These read/write heads were given to Jackson Research

by Al Bakowski, Bell&Howell's magnetic head specialist. |

| |

|