| |

|

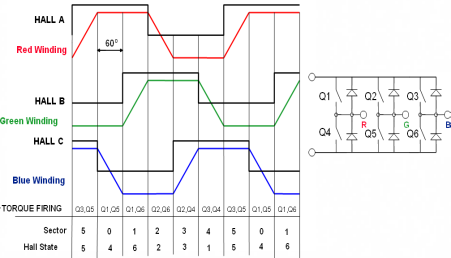

Six Step

The six-step waveform control was historically

the first method for controlling brushless machines, because

it was simple and was easy to impliment using discreet logic

chips. There were no MCUs available at that time. This method

is still in common use. |

|

| |

|

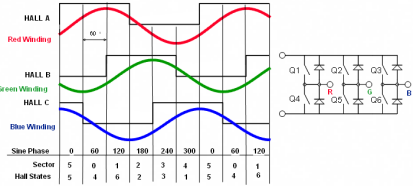

Sine Wave

The MCU or digital signal processor made the

sine wave controls feasible. There are a variety of algorithms

available to create sine wave drives using the identical hardware

as the six-step method. This method is most favourable where

the back-emf is also a sine wave. |

|

| |

PID

A proportional–integral–derivative

controller (PID

controller) is a generic control loop feedback mechanism

(controller) widely used in industrial control systems – a

PID is the most commonly used feedback controller. A PID

controller calculates an "error" value as the difference

between a measured process variable and a desired setpoint.

The controller attempts to minimize the error by adjusting

the process control inputs. In the absence of knowledge of

the underlying process, PID controllers are the best

controllers. However, for best performance, the PID

parameters used in the calculation must be tuned according to

the nature of the system – while the design is

generic, the parameters depend on the specific system. |

|

|

| |

Proportional Term

The proportional term (sometimes called gain) makes a

change to the output that is proportional to the current

error value. The proportional response can be adjusted

by multiplying the error by a constant Kp, called the

proportional gain.

A high proportional gain results in a large change in the

output for a given change in the error. If the

proportional gain is too high, the system can become unstable

(see the section on loop tuning). In contrast, a

small gain results in a small output response to a large input

error, and a less responsive (or sensitive) controller.

If the proportional gain is too low, the control action may

be too small when responding to system disturbances. |

|

|

| |

Integral Term

The contribution from the integral term (sometimes

called reset) is proportional to both the magnitude of the

error and the duration of the error. Summing the

instantaneous error over time (integrating the error) gives

the accumulated offset that should have been corrected

previously. The accumulated error is then multiplied by

the integral gain and added to the controller output. The

magnitude of the contribution of the integral term to the

overall control action is determined by the integral gain.

The integral term (when added to the proportional term) accelerates

the movement of the process towards

setpoint and eliminates the residual steady-state error that

occurs with a proportional only controller. However,

since the integral term is responding to accumulated errors

from the past, it can cause the present value to

overshoot the setpoint value (cross over the setpoint and then

create a deviation in the other direction). For

further notes regarding integral gain tuning and controller

stability, see the section on loop tuning. |

|

|

| |

Derivative Term

The rate of change of the process error is calculated by

determining the slope of the error over time (i.e., its first

derivative with respect to time) and multiplying this rate

of change by the derivative gain Kd. The magnitude of

the contribution of the derivative term (sometimes called

rate) to the overall control action is termed the derivative

gain, Kd.

The derivative term slows the rate of change of the controller

output and this effect is most noticeable close to

the controller setpoint. Hence, derivative control is used

to reduce the magnitude of the overshoot produced by

the integral component and improve the combined controller-process

stability. However, differentiation of a

signal amplifies noise and thus this term in the controller

is highly sensitive to noise in the error term, and can

cause a process to become unstable if the noise and the derivative

gain are sufficiently large. Hence an

approximation to a differentiator with a limited bandwidth

is more commonly used. Such a circuit is known as a

Phase-Lead compensator. |

|

|